Oct 21, 2024

Electric car batteries: technologies that are revolutionising mobility

Discover the new technologies that are improving the performance of the electric car battery, maximising range, efficiency and charging time.

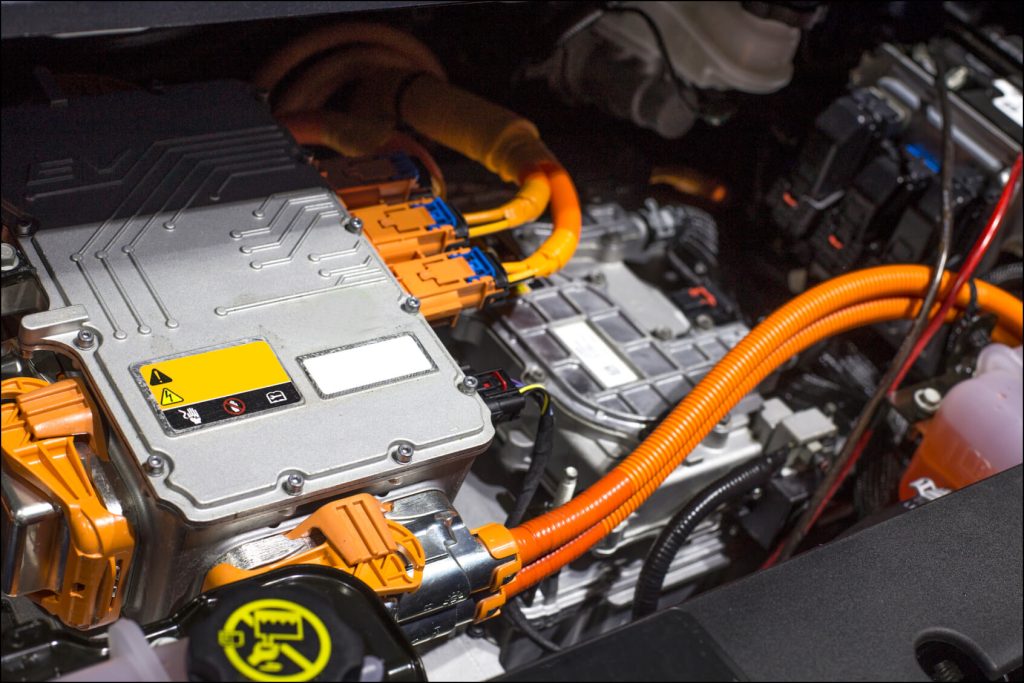

What really makes an electric car special? The answer lies in its battery: a fundamental element that not only powers the engine, but is the beating heart of the entire technology. But have you ever been curious to find out exactly how an electric battery works? Or what innovations are transforming the way we drive? In this article, we will discover together how different types of batteries are revolutionising the world of electric cars, promising increasingly efficient and sustainable performance.

How does an electric car battery work?

Let’s take a step back. Simplifying as much as possible, electric car batteries work according to the principles of electrochemistry: that is, they generate electricity by exploiting spontaneous chemical reactions. Every electric vehicle is equipped with a battery pack, a group of batteries consisting of several individual cells, all of which are the same. Each cell, called a galvanic cell, consists of three elements: an anode (negative electrode), usually made of graphite; a cathode (positive electrode), made of metal oxides such as nickel, manganese and cobalt; and an electrolyte, a liquid or viscous substance that allows the movement of ions between the anode and cathode..

When we drive, electrons flow from the anode to the cathode, generating the electric current that powers the electric motor and sets the wheels in motion. When the vehicle is recharged in a wallbox or charging station, the process is reversed: an external energy source pushes the electrons from the cathode to the anode, allowing the battery to regain charge.

New technologies for electric car batteries

All batteries are designed to withstand numerous charge and discharge cycles but, over time, this process can reduce their power, just as happens to the batteries in our smartphones. Although the operating principle is the same, there are different types of batteries, each with specific characteristics, advantages and disadvantages. Let us look at the most advanced ones together.

Solid-state batteries

Solid-state batteries owe their name to theelectrolyte, which in this case is in a solid rather than liquid state, made from materials such as sulphides or oxides, which ensure more efficient ion transit. Compared to conventional batteries, solid-state batteries can double the energy density and store more energy in less space and with less weight, which are crucial for improving the efficiency and power of electric vehicles. In addition, the liquid electrolyte is notoriously flammable, while its solid counterpart reduces the risk of fire and thermal instability, thus offering greater safety.

Another significant advantage is the recharging speed: some prototypes allow a recharge to be completed in just 10-15 minutes. On a single charge, an electric vehicle equipped with these batteries can travel up to 700 km or more. Due to the use of less rare materials and the reduced need for cooling systems, production costs are relatively low.

However, large-scale production of these batteries is still complex. Engineers are trying to optimise materials and processes to ensure consistent quality and high performance. Despite the prospect of long-term cost reductions, initial production costs are still high, which is why these batteries are, for the time being, only found in the most advanced models of electric vehicles. Finally, although they promise a long service life, solid-state batteries have yet to demonstrate the ability to cope with thousands of recharging cycles to compete with the longevity of current lithium-ion technologies.

Lithium-sulphur batteries

Lithium-sulphur batteries consist of a sulphur cathode, a lithium anode and a liquid electrolyte. When used, the ions move from the anode to the cathode, where the lithium reacts with the sulphur to form lithium polysulphides. This reaction achieves a higher energy density than other batteries, reaching up to 500 Wh/kg compared to 150-250 Wh/kg for conventional lithium-ion batteries. In practice, this translates into a significantly longer driving range for electric cars.

Another big advantage is that sulphur is a cheap material that is available in abundance. This means that production costs are lower than for batteries using other rarer and more expensive materials such as nickel or cobalt. In addition, sulphur is non-toxic and non-flammable, making these batteries safer and more sustainable.

However, there are also challenges. Lithium-sulphur batteries have a shorter service life due to the dissolution of polysulphides in the electrolyte, which leads to a loss of capacity over time, and they generally cannot withstand the same number of charge and discharge cycles as lithium-ion batteries. In addition, sulphur and its discharge products have low electrical conductivity, which requires the use of conductive additives that can reduce the overall energy density. During charge and discharge cycles, batteries undergo significant volume changes (up to 80%), which can cause mechanical degradation. In addition, lithium dendrites can form on the anode during charging, increasing the risk of short circuits and safety problems.

These batteries offer promising advantages in terms of energy density and sustainability, but require further development to overcome current limitations in terms of durability and reliability.

Sodium ion batteries

Sodium-ion batteries consist of a cathode made of materials such as iron-manganese-nickel compounds and an anode made of hard carbon or other suitable materials, and offer an energy density of between 90 and 160 Wh/kg, which is slightly lower than that of lithium-sulphur batteries. However, these batteries are characterised by being extremely economical due to the wide availability and low cost of sodium.

Another important advantage of sodium is its non-flammability, which allows batteries to operate safely even at high temperatures, without the risk of thermal instability. In addition, sodium is less toxic and more sustainable than metals such as cobalt, commonly used in other batteries. Sodium ion technology also requires a lower concentration of electrolytes, making production even more cost-effective. An additional benefit is that sodium ions do not form alloys with aluminium, allowing the creation of lighter building materials.

However, the energy density of sodium-ion batteries remains lower than that of lithium-ion batteries. These batteries also have a shorter lifespan due to problems such as mechanical stress caused by sodium ions, which accelerates their degradation. The technology is still in the early stages of development compared to lithium-ion, resulting in limited commercial availability and higher initial production costs due to a still immature supply chain. Although suitable forstationary energy storage, sodium-ion batteries may not be ideal for high-performance applications such as electric vehicles orconsumer electronics.

Advantages of the latest generation of batteries

As can be seen, all the latest generation batteries offer significant advantages for electric vehicles. Thanks to greater energy density,range has improved, allowing us to travel more kilometres with fewer stops for charging and less range anxiety. Energy efficiency has also increased, with faster recharging (some in just 10-15 minutes) and waiting times halved. In addition, the use of readily available and less toxic materials such as sulphur and sodium makes these batteries more sustainable, helping to reduce environmental impact. Choosing one battery over another depends on your individual needs for range, budget and sustainability: consulting an expert or the manufacturer can help you find the best solution for your electric vehicle.

The future of the electric car

The future of electric cars is getting more and more exciting, thanks to constant technological innovations. With batteries lasting longer, charging times getting faster and costs falling, they will soon become an affordable choice for many. Industry and researchers continue to work on solving outstanding issues, such as the large-scale production of more advanced batteries and the expansion of charging stations. Powering these vehicles with renewable energy will reduce CO₂ emissions even further, accelerating the transition to more sustainable mobility. In the coming years, electric cars could become the absolute protagonists on our roads, changing the way we move and helping to protect the environment for those who will come after us.

Purchase your EV Charger

Our expert will contact you to offer you the most suitable solution for you.